Superior structures

All subframes of our superstructures are made from non-welded metals that we can be bent up to 8 metres in length. Lack of welding ensures long service lifetime of the subframe, as well as giving it extra strength and durability.

Precision cut

All metal parts and metal holes for mounting bolts are precisely cut with TRUMPF TruLaser 8000 cutting machine. With this powerful tool, we can cut metals up to 8 meters in length and 2,5 meters in width. It also allows us to easily add a number of accessories to the subframe.

Strength and reliability

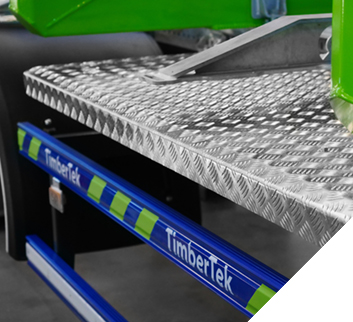

We use strong, durable steel of Strenx 650 that gives tightness to the subframe. All of our products are made with this steel and aluminium, which enhances the durability, prolongs the lifetime of the superstructure and maximises timber truck payloads.

Hot galvanization

All steel elements of the superstructure are galvanized in heat, giving it 100% lifetime guarantee against any corrosion.